Turbine Service Center

You can be sure when troubleshooting, performing a routine inspection or a complete refurbishment on your aircraft, we will excel with an uncompromising commitment to safety. Our maintenance division specializes on providing service to King Airs, Citations, Learjets, Falcons, Challengers and Hawkers.

Our technicians go through continual training from Simuflight and Flight Safety focusing on the latest trouble shooting information to work smart on your aircraft. We offer FAA designated airworthiness representatives services to assist with airworthiness certifications, import and export certificates and ferry permits.

To ensure the best customer value, we assign a crew chief to work on your behalf. Dedicated to your best interests the crew chief monitors your aircraft through every phase, giving you options and communicating with you to assist in making informed decisions.

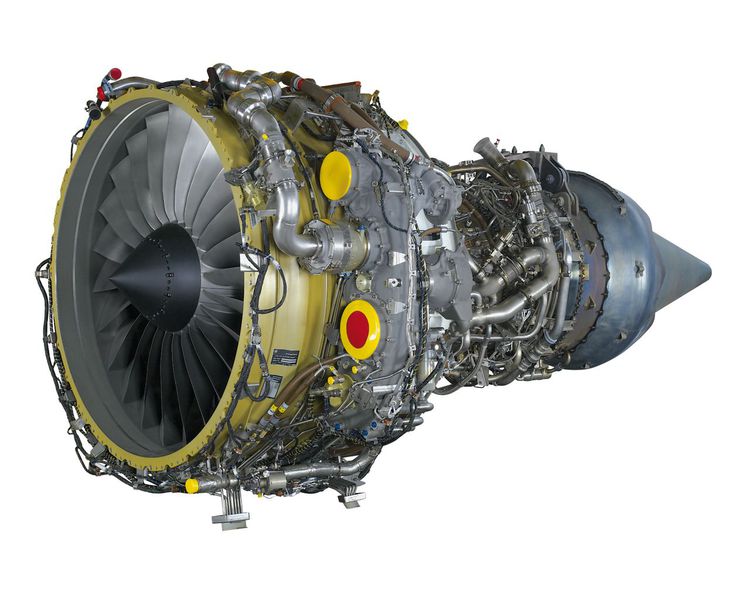

Pratt & Whitney, Canada PT6A (all series)

Hot section inspections and repairs (US Facilities only)

- Compressor turbine: re-blading, machining and balances

- Inner exit duct: repairs and reconstruction

- Combustion liner inspection: repairs and recertification

- Large exit duct inspection: repairs and recertification

- Compressor bleed valve: functional check and repairs

- Fuel nozzles clean and flow and repair: exchange kits available

- Power section/reduction gearbox inspection and minor repairs

- Line maintenance and rigging

- Engine overhaul management

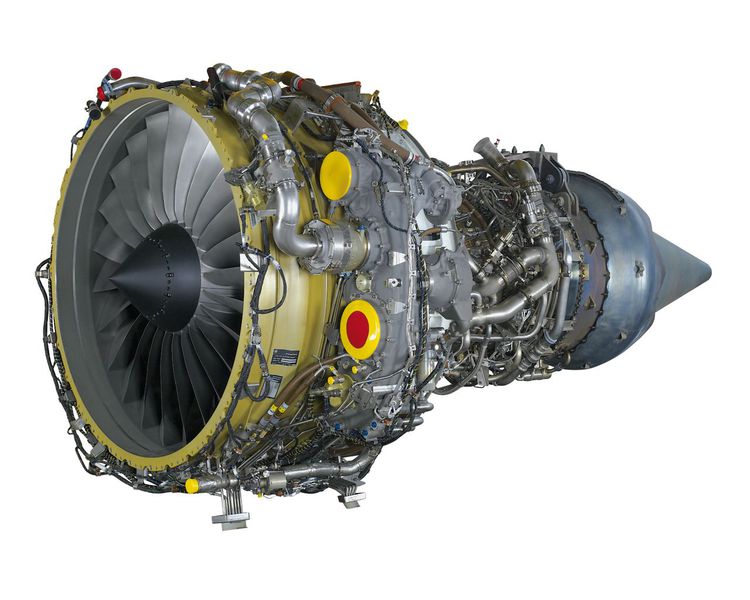

Honeywell TFE731

- MSP/JSSI work

- Routine Inspections

- Borescope Inspections

- Removal & Installations

- Engine Rigging

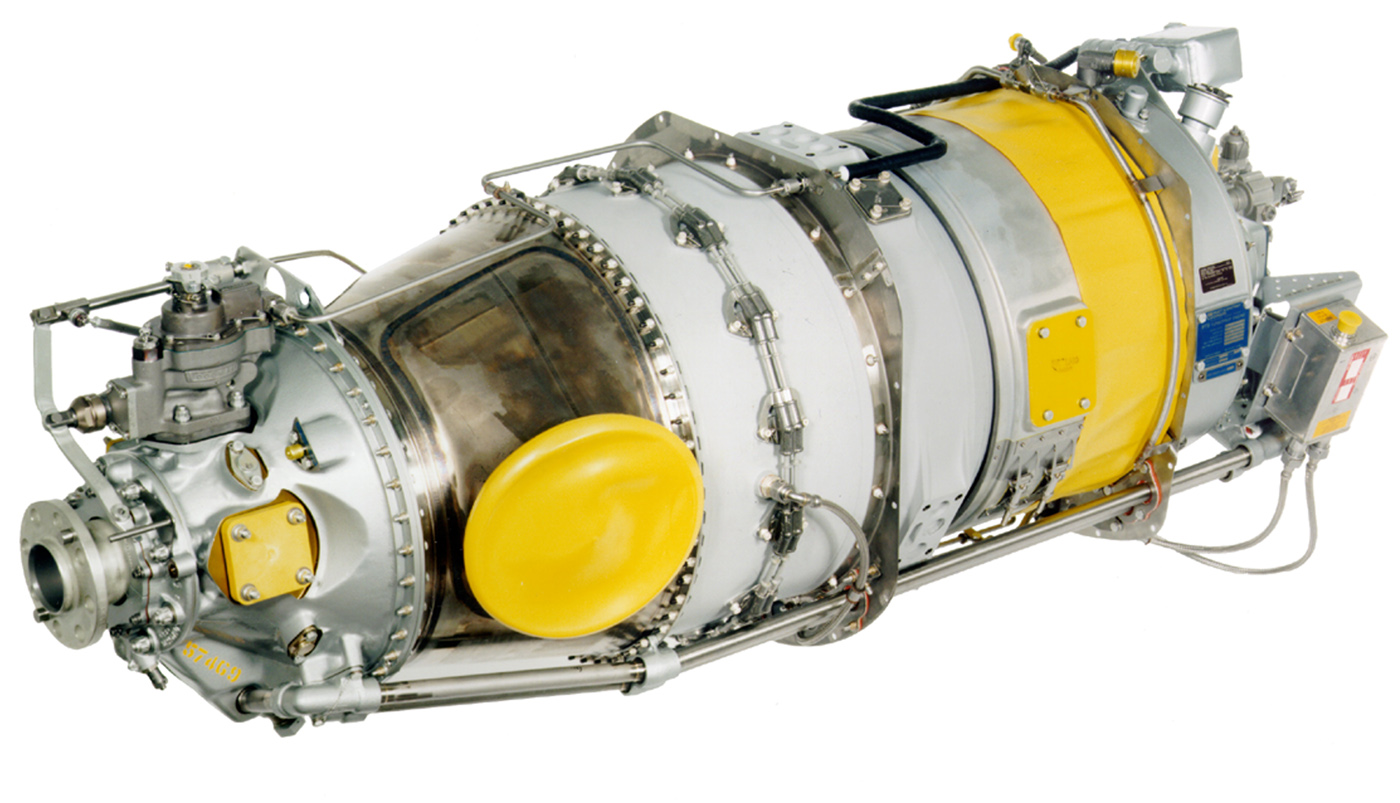

Pratt & Whitney, Canada JT15D

Applicable engines: JT15D-1/1A/1B/4/4B/4D/5

Hot section inspections and repairs

- Inner exit duct assembly: rework & pre-grind

- Outer exit duct assembly: clean, inspect and recertification

- Combustion liner: clean, inspect and recertification

- Fuel nozzles: clean, functional test and repair

- Line maintenance and rigging

- Engine overhaul management

General Electric CF34

- OnPoint/JSSI work

- Routine Inspections

- Borescope Inspections

- Removal & Installations

- Engine Rigging

FAA Designated Airworthiness Representative (DAR)

Import and export certificates

Ferry permits and DAR consulting

Special airworthiness certification

Technical Services

Nothing but perfection is acceptable when it comes to maintaining your aircraft. We have assembled a team with the expertise to provide maintenance services of the highest craftsmanship, precision and attention to detail. With multitude technical departments our teams will meet your schedule with seamless integration of services, facilities, and resources. With decades of experience in aircraft maintenance from light twins to Jets, we can perform a full range of airframe and engine maintenance.

Technical Services Offered:

Airframe Services - Engine Services - Avionics Service, Installation & Sales - Structural Repairs and Modifications - Interior and Paint Refurbishment

Landing Gear Overhaul

The landing gear is the only aircraft system without built-in redundancy – you need to rely 100 percent on its proper function. A very precise industrialized overhaul process, based on extensive in-house capabilities, is the primary reason that keeps our customers' vital undercarriages working properly.

A landing gear unit combines a multitude of parts. Its maintenance therefore requires a process chain with an outstanding degree of coordination. We have designed flow-principled workshops and provide vast in-house capabilities with state-of-the-art equipment at our landing gear overhaul facilities.

During overhaul, the landing gear proceeds through a sequence of predetermined stages, from disassembly to stripping, damage assessment, NDT and beyond. The disassembly of a landing gear unit sometimes brings surprises to light. Corrosion, for example, can call for very extensive repair work. To minimize episodes like this, we work closely with our line maintenance teams to optimize washing and lubrication protocols, resulting in measurable cost savings and reduced scrap rates.

Documentation plays a crucial role in landing gear maintenance, repair and overhaul. The high documentation requirements are driven by aviation law as well as commercial reasons. Our accurate documentation adds value to every landing gear by supplying a transparent history regarding the remaining life and airworthiness. This is important for operators as well as leasing companies and dealers. Moreover, as many parts in aircraft systems are life-limited, full traceability becomes a legal requirement. We assist our customers in obtaining missing documents to get the necessary complete back-to-birth documentation.

(Click thumbnails above to enlarge)